Seattle, Washington – Montreal, Canada, May 17, 2023, /OrthosSpineNews/ – Pacific Research Laboratories, Inc., the parent company to Sawbones® and Numalogics Inc., announce today that the results of a thorough validation study of a virtual standardized biomechanical test will be presented at the ASME VVUQ conference this week in Baltimore, and also announce a formal partnership to make these tests widely available to industry.

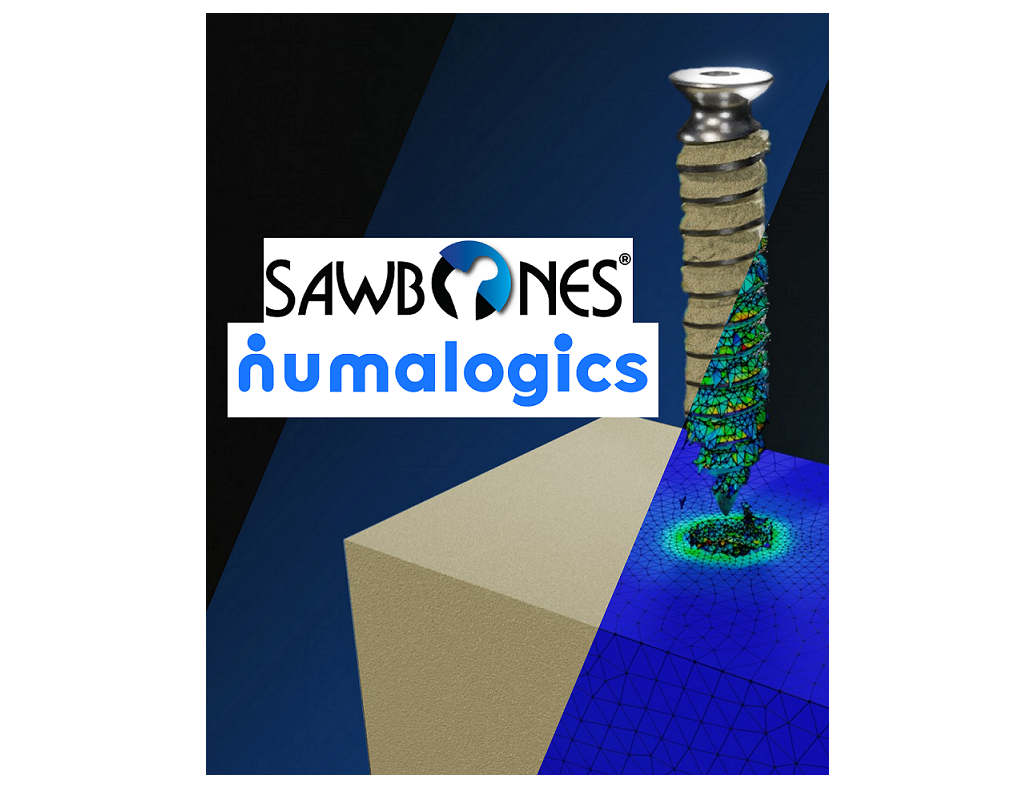

In the last 2 years both companies have worked collaboratively to develop accurate virtual models (Finite Element Models) of a standardized biomechanical test for orthopedic screws. ASTM F543, established by the American Society for Testing & Materials, is the specific standard that describes how orthopedic metallic screws are tested for performance. The standard specifies the use of polyurethane foam to act as bone surrogate, of which Sawbones® is the global standard.

The virtual model can be viewed as a virtual bench test whereby any metallic screw can be inserted into a virtual Sawbones polyurethane foam block and tested according to ASTM F543. The validation results of the model show that physical testing performed in real life, is accurately represented in the virtual test. This suggests that orthopedic implant designers and manufacturers can now design and test screws at a much lower cost and faster pace, as the prototyping phase can be shortened. Furthermore, the model offers a comprehensive evaluation of screw performance and valuable insights into bone damage mechanics to give opportunities for improvement.

Sawbones® is the world leader in supplying bone surrogate materials to the orthopedic industry and is consistently used to perform bench tests on new devices. With the new simulation software, testing with Sawbones® will be easier to do in a fast-paced virtual environment. Amy Posch, Design Engineer-Biomechanical at Sawbones® said: “Sawbones® strives to offer the most comprehensive, easy to use products that consistently simulate bone characteristics for physical testing. By adding computational simulation to our biomechanical test line, customers will be able to rank, analyze failure and optimize device designs more efficiently.”

Numalogics is a leader in computational modeling & simulation (CM&S) in the orthopedic industry and is one of the first companies in the world to fully automate virtualized ASTM standards. Eric Gaudreau, President of Numalogics, said: “We are very pleased with the validation results. This takes us one step closer to causing a paradigm shift in medical device development whereby R&D and regulatory approval can be accomplished with CM&S. We hope to develop more validated models alongside Sawbones as we are grateful to have a trusted partnership with them.”

Sawbones® and Numalogics have entered an agreement whereby the virtual testing models would be made widely available through Sawbones® sales channels. It is expected to be released before fall 2023. A white paper detailing the validation results may be seen on the Numalogics website at www.numalogics.com.

About Sawbones®

In addition to supplying the world’s best medical procedure simulation models, Sawbones® offers a complete range of composite bones and test materials for orthopaedic experimental and computer simulated biomechanics. Designed to simulate the physical properties of human bone; these materials offer a more reliable test bed for biomechanical studies than cadaveric specimens. As an orthopaedic research community, Sawbones® has been qualifying and using biomechanical test materials for over 30 years with their use becoming more prevalent in scientific journals. Sawbones® are an active member of ASTM and ISO subcommittees for medical devices and implants for surgery.

About Numalogics Inc.

Numalogics specializes in computer modeling and simulation for the medical device, sports equipment, and military industries. In addition to providing consulting services that can help solve product development and innovation challenges, Numalogics is carving a path to develop easy-to-use software applications that would allow product innovators to perform simulation testing, without requiring the dedicated skill and experience in computer simulation. To ensure models are verified and validated, Numalogics is an active contributor to the ASME V&V 40 Committee.