Revolutionary Scandinavian Total Ankle Replacement (STAR® Ankle) System Now Includes Vitamin E-Blended Polyethylene Insert

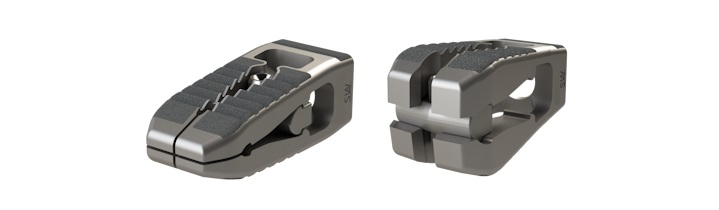

WILMINGTON, DE, August 19, 2024 – Enovis™ Corporation (NYSE: ENOV), an innovation-driven medical technology company, proudly unveils its Scandinavian Total Ankle Replacement (STAR® Ankle), now with new e+™ Polyethylene. Recent U.S. Food and Drug Administration (FDA) approval makes STAR® Ankle the first and only mobile bearing ankle system with e+™ Polyethylene in the United States.1 The implant’s new vitamin E-blended e+™ Polyethylene insert will offer improved durability, stability, and longevity.1

“With e+™ Polyethylene, we uphold our commitment to the advancement of our total ankle portfolio, merging full oxidative resistance with the time-tested design of the STAR® Ankle,” says Gary Justak, President and General Manager of Enovis Foot & Ankle. “Building upon the proven success of the STAR® Ankle epitomizes our culture of advancing foot and ankle solutions and elevating patient treatment options. We don’t just set the standard—we redefine it.”

e+™ Polyethylene contains the free radical-neutralizing antioxidant vitamin E; as a result, the material resists oxidation and maintains consistent wear rates and stable mechanical properties over time. In contrast, other highly crosslinked polyethylenes are remelted during manufacturing to neutralize free radicals2, a process that can reduce their mechanical strength by up to 12%.1,3

“After extensive clinical experience with this superior material in knee and shoulder implants, along with years of laboratory testing, I expect improved patient outcomes through increased polyethylene longevity. This builds on the outstanding STAR® Ankle long-term metal-component survival rates seen in multiple clinical studies,” stated Dr. Gregory Lundeen, a foot and ankle orthopedic surgeon at Reno Orthopedic Center.

Combined with the recent release of STAR Patient Specific Instrumentation (PSI), the STAR+ Experience represents Enovis’ commitment to continuous improvement, aimed at enhancing patient satisfaction and outcomes. The integration of e+™ Polyethylene in the STAR® Ankle continues to enhance the remarkable success of this implant, which has been used globally over 40,000 times across its 37-year history.4

For more information about the STAR® Ankle with e+™ Polyethylene and Enovis’ innovative foot and ankle solutions, please visit https://www.enovis.com/products/star-ankle.

About Enovis

Enovis™ Corporation (NYSE: ENOV) is an innovation-driven medical technology growth company dedicated to developing clinically differentiated solutions that generate measurably better patient outcomes and transform workflows. Powered by a culture of continuous improvement, global talent and innovation, the Company’s extensive range of products, services, and integrated technologies fuels active lifestyles in orthopedics and beyond. For more information about Enovis, please visit www.enovis.com.

Media Contact

Diana Aldermae

Enovis™ Foot & Ankle

Diana.Aldermae@enovis.com

Individual results may vary. Neither Enovis™ Corporation nor any of its subsidiaries dispense medical advice. The contents of this release do not constitute medical, legal, or any other type of professional advice. Rather, please consult your healthcare professional for information on the courses of treatment, if any, which may be appropriate for you.

References

Dr. Gregory Lundeen is a consultant for Enovis™ Corporation.

- e+ testing data on file. Bench test results not necessarily indicative of clinical performance.

- Jennings et al. The influence of femoral condylar lift-off on the wear of artificial knee joints. Proc Inst Mech Eng [H]. 2007 Apr;221(3):305-14.

- S.M. Kurtz. “The UHMWPE Handbook: Ultra-high Molecular Weight Polyethylene in Total Joint Replacement”. Elsevier Academic Press, 2009.

- Enovis® internal document: Includes world-wide implantations of all generations; newest generation has over 40,000 world-wide from 1998-2022.