Focusing the optimization of immunological response and tissue integration with implant surfaces.

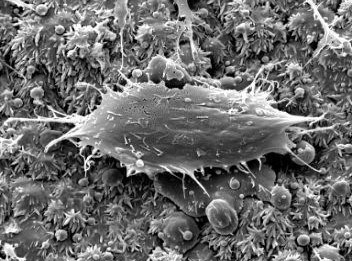

LONGMONT, Colo., Oct. 13, 2022 /PRNewswire/ — Implant Surfaces LLC and CMDC Labs have agreed to expand a joint development effort to pursue immunological and tissue integration research relating to machined and 3D-printed titanium implantable medical devices. For the last decade, the companies have collaborated to optimize 6 unique titanium topologies that preferentially encourage targeted cell lines to attach to medical devices: for example, direct Osteoblast (bone cell) attachment to spinal implants while minimizing fibroblast interference. https://implantsurfaces.com/specialty-cell-attachment/

Working together, the companies will now more broadly analyze the body’s immune response, microbial response, and relative surface biocompatibility of well-established post-treatments for titanium and titanium alloy devices, with particular attention to 3D-printed medical implants. Recent literature suggests some surface post-treatments may trigger negative bacterial and immunological response to a device.

“Our recently expanded research capabilities at CMDC Labs will allow thorough investigation of the bioactive coatings developed by Implant Surfaces by analyzing specifically how the immune response to a 3D-printed titanium surface’s post-treatment affects cell attachment and proliferation in a newly developed in vitro diagnostic model. In addition, we hope that delivering that specific biological and chemical feedback exactly when needed will speed development,” said Dan Storey, Ph.D. and CEO of CMDC Labs.

Implant Surfaces is known within the spinal market for creating a nano-engineered titanium coating applied to polyetheretherketone (PEEK) implants that significantly enhances bone cell (osteoblast) attachment while nearly eliminating fibroblast encapsulation. To date, over 50,000 implants with the company’s IntimateBond™ Osteoblast coating have been used in Spinal and Foot & Ankle procedures.

Both companies expect the methods used in this joint project will speed up surface development dramatically. Michael Paul, Director of Equipment and Processing Technology for Implant Surfaces said, “Closely matching surface development with the advanced immunological testing we need, exactly when and where we need it, will provide near real-time feedback on the entire series of nano modifications required to deliver the surface’s target electrical and chemical properties. Eliminating scheduling, availability and waiting time will also save a tremendous amount of time.”

“We’re hoping to prove out this approach with Implant Surfaces so we can make it available to other companies that need biological testing tightly coordinated with surface or product development,” said Christina Thomas, VP of Testing Operations for CMDC Labs.

About Implant Surfaces

Implant Surfaces’ foundational research began in 2005 with an antimicrobial coating, Dual+ AgO™. after significant research including in vivo studies, the company began commercial production of its titanium osteoblast attachment coating under a long-term supplier agreement which is no longer exclusive. The company’s mission is to improve the biocompatibility and healing properties of medical devices implanted throughout the body. For more information about Implant Surfaces, please visit the website www.implantsurfaces.com

About CMDC Labs

CMDC Labs is a commercial provider of bioactive surface testing, microbiology testing and immune response testing for medical device manufacturers and researchers. CMDC Labs’ goal is to offer multiple levels of testing and analysis as well as development that supports critical early-stage evaluations of cell/tissue behavior and interactions with medical device surfaces. The company offers multidisciplinary experience in mammalian cell testing and microbiology. CMDC Labs represents an ideal complement to the plasma physics expertise of Implant Surfaces. For more information on CMDC Labs please visit the website www.cmdclabs.com

SOURCE Implant Surfaces